Edwin Cramer, Laboratory Supervisor at Bureau Veritas Rotterdam: “We use Oxford Instruments’ benchtop MQC+23 NMR analyser to measure solid fat content.”

Traditionally, the Bureau Veritas laboratory in Rotterdam was specialized in petrochemical testing. When the facility decided to expand into edible oils and fats analysis, it needed an overhaul. Among the equipment it acquired was a benchtop NMR analyser, which has made the analysis of Solid Fat Content (SFC) a piece of cake.

Bureau Veritas extended its existing building to house a new, state-of-the-art laboratory. The branch renovated and refurbished the existing facility, too. Laboratory Supervisor Edwin Cramer says he’s pleased with the extra space. “We had really outgrown our old facilities,” he says. “It had become impossible to create optimum routing.”

Once Bureau Veritas decided to expand into edible oils and fats analysis, renovation became a must. The new lab meets all current requirements and preferences regarding growth chambers, fume extraction, and air quality. The lab made big investments in equipment, too, as Cramer explains. “Customers expect their test results to be available ever faster. So we needed more equipment,” he says. “The new equipment can also handle much lower detection limits. And with all the extra space, we can now strictly separate the various product groups—gasoline, diesel, kerosene, methanol, and agricultural products—to prevent cross-contamination. The new lab is great to work in.”

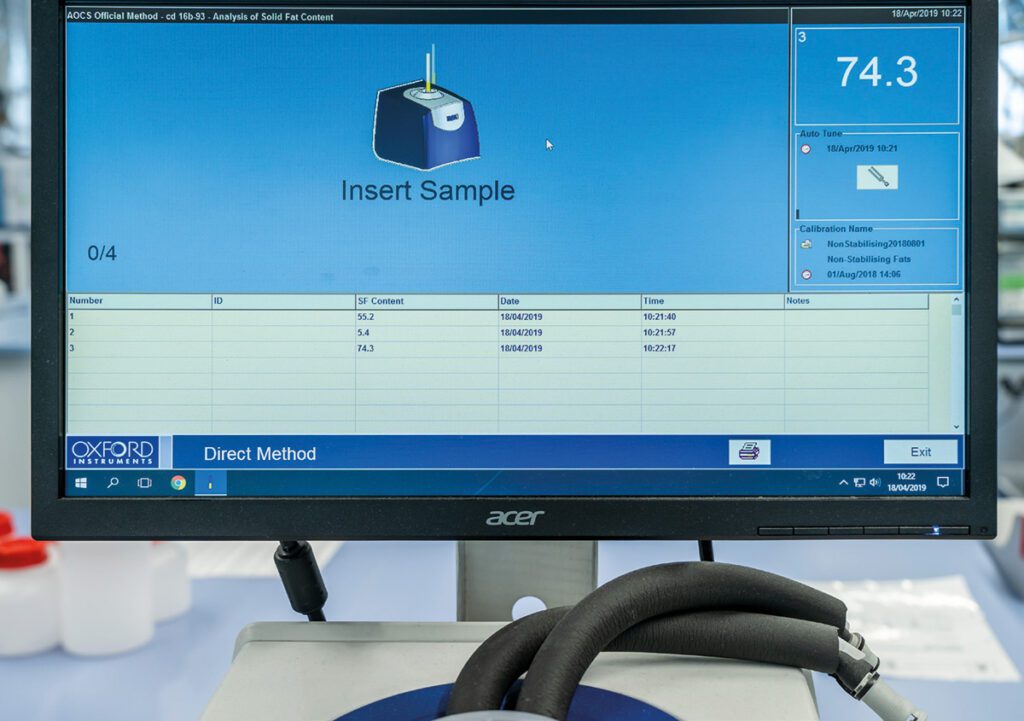

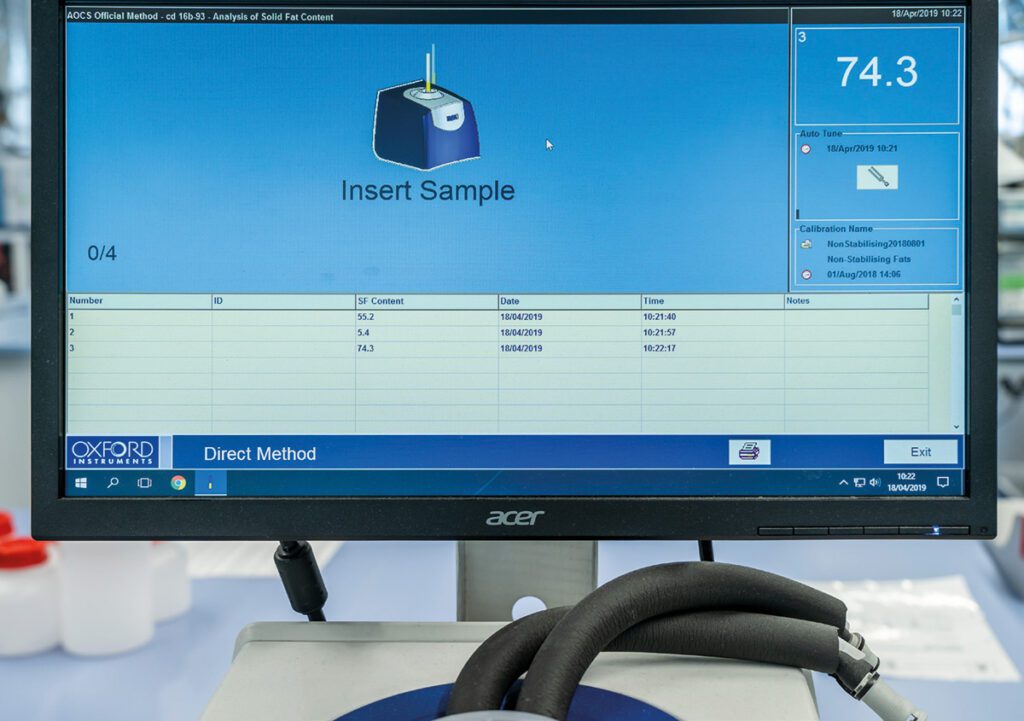

The new Bureau Veritas lab where solid fat content measurements are taken using

a benchtop NMR analyser. The screen shows which steps need to be followed | Photo: Marco Vellinga

“This ISO 8292 certified equipment is lot easier to use and much faster”

Edwin Cramer

Introduction to Nuclear Magnetic Resonance

Currently, the agricultural products section mainly analyzes palm oil and used cooking oil (UCO). It’s a promising direction, according to Cramer. “This is a growth market that we are going to expand to other products and analyses. That is our way of preparing for the forthcoming energy transition.”

UCO is available in many grades ranging from clean, to acidic, to full of dregs. “We determine the quality based on the standards set by the Federation of Oils, Seeds and Fats Associations (FOSFA),” says Cramer. “In addition, our lab has been ISO 17025 certified by the Dutch Accreditation Council since March 2019.”

The analyst hits a button, puts the sample in the NMR analyser, and gets the result | Photo: Marco Vellinga

The lab’s new services required new equipment that its analysts had never used before. To determine solid fat content, Bureau Veritas purchased Oxford Instruments’ benchtop MQC+23 NMR analyser from Salm en Kipp. This analyser complies with many international standard test methods used in agro-food and petrochemicals. It is easy to use and versatile, Cramer says.

“It can be used for all sorts of analyses, such as measuring oil and fat content of seeds and foodstuffs, measuring spin finish (oil) on natural and synthetic fibers, oil in wax, wax in oil, hydrogen content in fuels in accordance with ASTMD7171, and fluoride content in powders. Currently, we’re just using it to measure solid fat content, though.” In the old days, SFC was determined using wet tests. “But this ISO 8292 certified equipment is a lot easier to use and much faster,” Cramer adds. Bureau Veritas decided to go with the MQC+23 at a seminar where Salm en Kipp demonstrated the analyser and its many applications. “Its versatility appealed to us,” he says. “It felt right. It was precisely what we were looking for.”

Plug & play

In the past, going with Nuclear Magnetic Resonance meant investing in costly equipment with a giant footprint. These days, there are smaller and less expensive options. “In our case, we went for a small, benchtop model that is relatively affordable,” says Cramer. The lab uses the analyser’s standard software that can be configured by the manufacturer to meet end-user preferences.

“They spent two days setting up and configuring the analyser to our specifications, and then taught us how to use it,” Cramer says. “It was plug and play, and everything was up and running easily. It’s effortless to find earlier results and calibration data. Some instruments have many applications and options you don’t need that get in the way of user-friendliness. We’ve also seen equipment that won’t allow you to secure your settings. So when you start measuring, you suddenly realize another user has changed the settings. But there’s none of that with the MQC+23. After sample prep, the analyser indicates which steps you have to take. You put the sample in, push a button, and get your results. If only all lab equipment was this simple to use.”

The user interface of Oxford

Instruments’ NMR analyser guides users through every step | Photo: Marco Vellinga

“Benchtop NMR makes solid fat content analysis a piece of cake”

Small samples

The measurements take just a few seconds. “The test results are stable, so if you measure the same sample two days in a row, you get the same results. And the results are very accurate too,” says Cramer. “I guess if you wanted to trace the geographical origin of olive oil, you might need an analyser that is more sensitive, but for our purposes, this analyser is more than good enough.” Oxford Instruments’ benchtop NMR analysers are available in a 23 MHz and a 5 MHz version. Bureau Veritas opted for the MQC+23 because “the 23 MHz version’s sensitivity makes it suitable for measuring small samples of just a few milliliters,” Cramer says. “The 5 MHz version can handle larger sample sizes, which allows you to measure more heterogeneous samples, such as seeds or foodstuffs. But that’s not something we need right now.”

Leendert van der Ent

Translation: Word’s Worth