Spetec can now offer an inexpensive way of creating partial sterile clean air areas. The characteristic design feature is a laminar flow module equipped with a high quality fan and a filter system made up of a pre-filter and a high-performance filter (HEPA 14). The filter classification HEPA 14 indicates that this filter is capable of filtering out 99.995 % of all particles with a diameter 0.5 µm.

The size of the module is variable, depending on the precise application. The tried-and-tested approach to creating high quality clean air workplaces, located either in an enclosed clean room or in air-conditioned rooms, is to suspend a module above the workplace.

For some 20 years now, Erding-based Spetec Gesellschaft für Labor- und Reinraumtechnik mbH have been designing and building clean rooms of various sizes that allow flexible design, manufacture, and installation to meet customer requirements and needs. To date, these products have been used in a whole range of different areas of application. They are installed in all kinds of industrial buildings, wherever there is a need for especially clean working conditions and where an extremely sterile environment is needed or recommended.

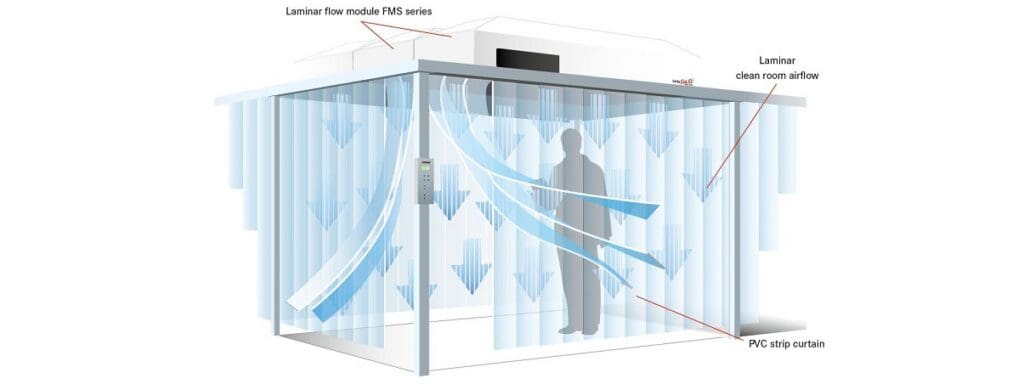

The laminar flow of clean air creates a restricted zone that is sterile and free of particles. If larger clean air zones (clean room cells) are needed, it is also possible to install and connect several modules alongside each other. If the intended clean room contains equipment or furniture, Spetec recommends a low-turbulence flow of clean air to ensure that air is exchanged throughout the space.

Spetec manufactures the modules and all accessories in compliance with GMP (good manufacturing practice) standards and is accredited accordingly. In addition to the standard sizes shown in the company’s catalog, a number of options are available.

In-house fabrication facilities allow custom sizes to be manufactured to meet specific customer needs. Spetec’s experience shows that the clean air area can be any size up to 250 m². Today’s modern modules can be suspended at any height or secured to the ceiling. They are quiet in operation and feature a filter change indicator. The filter is easy to replace. The period for which the filter remains sufficiently effective depends on the quality of the air in the room. In some cases, a service life of four years and more has been recorded in practice.

With new builds and renovation projects, modules like this can also be recessed in the ceiling. This method of producing clean air represents an inexpensive alternative to complex, fully enclosed clean rooms. If entrances and windows are well sealed, a similar level of air cleanliness can be produced if the systems run permanently.

The characteristics and quality categories for clean rooms are laid down in the following standards: DIN EN ISO 14644, Part 1 (classes 1 – 9), DIN EN ISO 14698, Parts 1-3 and VDI 2083, Parts 1-18 (classes 0 – 7); US Federal Standard 209E (classes 1 – 100 000) or in the EC GMP Guidelines (classes A – D).

The things that have the greatest impact on keeping objects clean are the ambient air and people. Clean rooms are also contaminated as a result of particles being transported through the air, the introduction of particles on technical surfaces and the production of particles by equipment, staff and running processes. In a class 8 clean room, more than 600 million particles (> 0.5 µm Ø) per cubic meter are given off per person per shift by the skin and clothing alone.

This figure, along with other counts of particles of the same size given off when staff in protective clothing move (when sitting with gentle movement of the lower arm: 20,000; when standing up: 50,000 and as a result of slow walking: 80,000 per person) is based on data from the Fraunhofer Institute for Manufacturing Engineering and Automation (IPA) in Stuttgart.

In addition to microdroplets, dust and smoke particles, the ambient air mainly contains bacteria (~ 0.5 – 50 µm Ø) and viruses (~ 0.005 – 0.1 µm Ø). Bacteria that are resistant to antibiotics can be extremely dangerous for humans, particularly in medical environments. Most of these particles, however, are not hazardous to healthy people. The situation is different for sick people, particularly those with an acute immune deficiency or with open wounds, and who must be treated in the ambient air or in air-conditioned rooms with air circulation systems.

To achieve an even more favorable air cleanliness classification, Spetec recommends separating the room with a strip curtain. Within this space, it is then possible to work in a particle-free, sterile environment. Sensitive equipment or tools can be used and stored there. All this can be achieved without the need for any significant building work.

In summary, it can be seen that an expensive, fully enclosed clean room may not always be needed, particularly when operators need to move around in the room. The inexpensive, flexible Spetec modules can also be fitted or suspended as required.