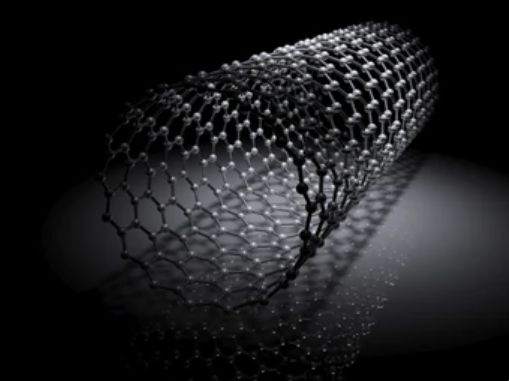

Carbon Nanotubes (CNTs) are nanostructured materials made by curling layers of graphene sheet together. They have very specific physicochemical characteristics such as extreme strength, high conductivity and flexibility, and so they are extremely important for contemporary science and technology studies.

Common Production Methods

Production techniques of carbon nanotubes are Chemical Vapor Deposition (CVD), Arc Discharge and Laser Ablation primarily. All these approaches are different, they have pros and cons, and they can be used in different contexts.

Chemical Vapor Deposition (CVD)

The most widely applied technique to make large quantities of carbon nanotubes is CVD. It works by splitting carbon gases (eg, methane or acetylene) under extreme heat, with nanotubes formed on the surface of a metal catalyst. It can be done at relatively lower temperatures, from about 400 to 900°C, and so is more efficient in terms of energy use.

Advantages: CVD is capable of high yield and purity carbon nanotubes and works on all substrates, such as ceramic tiles, cement, and fiberglass. What’s more, CVD is customizable and can be achieved using carbon as a solid, liquid or gas.

Disadvantages: CVD is a good process for mass production, but we need strict control over reaction parameters to get good nanotubes.

Carbon nanotubes were first created by arc discharge. It’s made by creating a high-voltage arc between two carbon electrodes that condenses carbon vapour into nanotubes in an uncooled environment. But the carbon nanotubes that come from this approach are usually dirty and need to be filtered.

Advantages: Arc discharge is a very quick and simple process preparation that doesn’t need complicated equipment or expensive materials. This can be utilised in laboratories or for industrial production, which it could very well be used in.

Disadvantages: Aerial-deposition carbon nanotubes can often contain various kinds of impurities such as carbon soot, catalyst metal residues, and amorphous carbon. These impurities need more cleaning, which costs production time and complexity.

Laser ablation is an efficient process using a high-energy laser beam to vaporize a graphite target creating nanotubes in an inert gas. It can be carried out at room temperature, but usually results in only single-walled carbon nanotubes.

Advantages: Laser ablation is fast to produce quality carbon nanotubes and can be done at lower temperatures, which is good for certain niche applications.

Disadvantages: This is a low yield process, and not for large scale production.

Each approach has its own applications and pros and cons. The choice of the right synthesis technique will vary with the application and the size of the manufacture.

Detailed Step-by-Step Process

Preparation of the Substrate

In CVD, the substrate used is very important. The most used substrate materials are silicon, silicon oxide, and aluminum oxide which have a good thermal and chemical stability.

Catalyst Selection and Deposition

CVD works on the basis of the catalyst. Transition metals like nickel (Ni), iron (Fe) and cobalt (Co) are all common metal catalysts. These catalysts are dedeposited on the substrate by physical deposition (sputtering) or chemical deposition (ammonia etching).

Gas Flow and Temperature Control

Carbon dioxide gasses (like methane, acetylene or ethylene) are pumped into the reaction vessel and breakdown in a furnace at very high temperatures. The reaction temperature should be between 650°C and 900°C for growth of carbon nanotubes. Additionally, the gas flow has to be exactly balanced so that the reaction can take place at the best possible conditions.

Catalyst Type and Size

The rate, diameter and shape of growth can be changed using different catalysts for carbon nanotubes. Nickel catalysts, for instance, are usually used for single-walled carbon nanotube growth, but iron catalysts work better for multi-walled carbon nanotube growth.

Reaction Temperature and Pressure

Carbon nanotube growth depends on temperature. Carbon nanotubes at higher temperatures yield and are more pure, but they use more energy. What is more, reaction pressure can affect the diffusion of gas molecules and reaction rate, and it is normally carried out at atmospheric or a little less.

Safety Considerations

For CVD, especially the operating environment must be safe. Because of the presence of temperatures and harmful gases, workers should use the right safety equipment and ventilate the area.

Equipment Requirements

CVD machinery mainly includes reaction chamber, heat exchanger, gas supply system, and gas flow control. Reaction chamber must be heat-resistant and sealing properly to prevent gas escape.

In all of these steps and safety measures, good-quality carbon nanotubes can be manufactured by chemical vapor deposition method. The process can be used for small laboratory production as well large industrial production.

carbon nanotube sheet