Spetec GmbH has grown into one of the world’s major manufacturers of peristaltic pumps, which are now produced both as made-to-measure units and as OEM versions in a wide variety of types.

And one thing that these types of pumps always need is tubing. Peristalsis refers to the synchronous contraction of the muscles in hollow organs that propagates as a wave and transports the contents in a given direction. This is the way in which organs such as the human esophagus or intestine work, and they act in the same way as the pump tubing. In humans, hollow organs such as these are of exceptionally high quality, which often allows them to do their job reliably for 80 years or more. This is an indication of how high the quality of the tubing material needs to be in peristaltic systems in order to guarantee acceptable durability. This required decades of development, since the conditions of use were, and still are, so varied.

And who should know better what degree of elasticity and durability the tubing needs when subjected to constantly alternating contraction and relaxation phases than the people who design and manufacture the pumps. Not only that, constant communication with the users is an invaluable source of knowledge about the fluids being transported. It is obvious that aqueous, acidic or alkaline fluids have an entirely different effect on the interior of the tubing from organic solvents, for instance. And so it is only logical that Spetec, a manufacturer of peristaltic pumps, also manufactures the associated tubing themselves.

Nowadays, tubing is manufactured for use in analytical chemistry, for instance in flow injection analysis (FIA, continuous flow apparatus), as well as for medical, pharmaceutical and biochemical engineering and other general laboratory applications. The materials used are PVC Standard , Polyurethane, Solvent Flex (solvent-resistant), Santoprene®, Silicone and Fluoro rubber (comparable to Viton).

A data sheet is available for each of the materials and can be obtained on request.

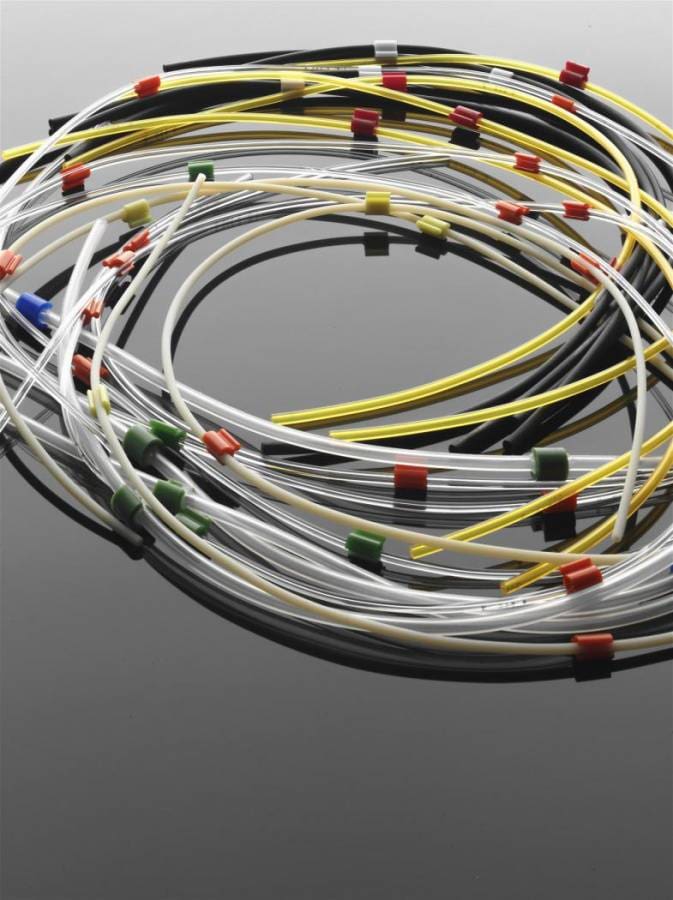

All tubing is available in a variety of configurations. The tubes come fitted with two or three bridges as standard. On request, however, more bridges can be fitted at different intervals to suit the application scenario. Tubing can also be supplied in more than 21 color combinations. The color combination of the bridges determines the internal and external diameter of the tubing. This makes it easy to identify what tube you need at any time.

The internal diameters of the tubing range between 0.12 mm and 3.2 mm. These are suited to the requirements of many dealers and end users.

The entire range of tubing that we manufacture covers more than 450 items, most of which are available from stock.

Special tubes manufactured to customer requirements can be also supplied at short notice.