Keratinase is an extracellular protein hydrolysis inducing enzyme that degrades insoluble keratin substrates. This enzyme can hydrolyze hair, feathers and collagen in wastewater systems during wastewater treatment. In addition, it can be used in the food industry and in the manufacture of livestock feed, among others.

Keratinase is an adaptogenic enzyme that is produced only when an inducer (keratin) is introduced into the microenvironment. Keratinase is extracted from a variety of microorganisms and has a wide range of applications in many industries and major ecological applications such as feed, leather, pharmaceuticals, and food.

Mechanism of action

Because the mechanism through which each bacteria destroys keratin is different, the end product differs as well. Certain fungi break disulfide bonds by secreting sulfites on the mycelium surface and reducing the acidic conditions, while Streptomyces produces intracellular reductase. Water-insoluble keratin, on the other hand, can only survive outside the cell in the form of granules. Since it necessitates insoluble keratin in frequent proximity with cells, disulfide bond reduction can only happen outside of the complete cell with significant metabolic capabilities, very possibly in the cell-bound redox system on the cell membrane.

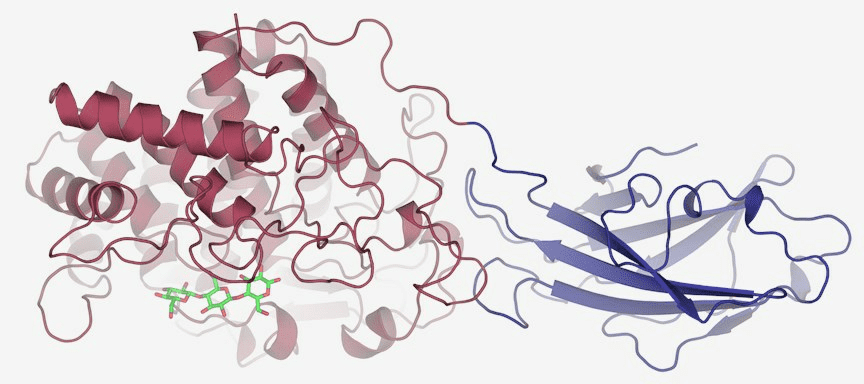

The disulfide bond reduction is then carried out by a cell-linked redox pathway in white high-temperature actinomycetes. Keratinase enzyme possesses both disulfide reductase and polypeptide hydrolase action. The breakdown of keratinase is currently thought to be separated into three stages: denaturation, hydrolysis, and transamination. Firstly, the disulfide reductase reduces cystine (-S-S-) to cysteine (-SH), causing the high-level composition of keratin to dissolve, resulting in degenerative keratin protein. Polypeptide hydrolase progressively hydrolyzes the degenerative keratin protein into polypeptides, oligopeptides, and free amino acids. Finally, transamination produces ammonia and sulfide, which totally hydrolyzes keratin.

Industrial Production of Keratinase Enzyme

In an effort to match current industry demands, fermentation is required to generate these enzymes on a large scale. Fermentation factors like carbon source, nitrogen source, temperature, and others must all be optimised because they influence keratinase enzyme synthesis. Industry waste, like feathers, can be incorporated into the culture media. Different wastes, like wheat and soybeans, can also be employed as a substrate for keratinase enzyme production.

Keratinase enzymes must be purified before they may be used for enzymatic characterization and other purposes. A variety of methods can be used to achieve a high-purity keratinase enzyme. Purification procedures include ammonium sulphate precipitation, gel filtration chromatography, and ion-exchange chromatography. To acquire a large quantity of enzymes, methods like the aqueous two-phase system can be used.

Application of Keratinase Enzyme

Keratin is considered good carbon, nitrogen, and sulfur that can be transformed into a variety of compounds in nature. Because of their propensity to break down keratins, keratinase enzymes have a wide range of industrial and biotechnological applications:

Livestock Feed Industry

Leather Industry

Detergent Industry

Fertilizer Industry

Pharmaceutical & Cosmetic Industry

Keratinase Enzyme Applications in Other Industries

Keratinases have been shown to successfully degrade infectious prion proteins, which are fibrous and sheet-dominated proteins. PWD-1 keratinase efficiently destroys disease-causing prion protein, with 100% breakdown of the extremely infectious prion protein. The activity of keratinase on fibrous and resistant keratinous residue serves as a starting point for this mechanism. Keratinase might potentially be useful for the treatment of industrial effluents. The extraction of glucocorticoids from avian feather biomass was facilitated by keratinase from Bacillus sp. C4.

More at our website.